In a nutshell:

EMO 2025 will showcase plug-and-produce using OPC UA information models (umati) combined with Time-Sensitive Networking (TSN) for determinism. The near-term reality: OPC UA is mature for interoperable data, TSN is production-ready for bounded-latency Ethernet, and convergence is happening in stages.

The winning approach pairs: OPC UA for standardized semantics (Machines/Machine Tools), TSN-capable switches/NICs for time-aware transport, and robust security/clocking. Retrofit paths exist via edge gateways for legacy CNC and IO.

Buyers should demand conformance-tested OPC UA Companion Specs, TSN feature coverage (Qbv/Qbu/Qci/AS/CB), microsecond-grade time sync, and IEC 62443-aligned security.

For years, manufacturers have wanted interoperable data models and Ethernet that behaves deterministically under load. In 2025, those ambitions are converging into deployable practice. As visitors head to EMO 2025 in Hannover, three acronyms will anchor many connectivity conversations on the show floor: OPC UA for standardized semantics, umati for ready-to-use machine tool information models, and TSN for bounded-latency transport on standard Ethernet. The common thread is pragmatic convergence: operators are standardizing on OPC UA to expose machine data uniformly, adopting umati to shorten integration from weeks to days, and introducing TSN selectively where cycles and jitter matter.

OPC UA’s strength is not the transport—plenty of plants will continue to use classic client/server and brokered MQTT—but its semantics. The Machinery Base (OPC 40001-1) and Machine Tools (OPC 40501-1) Companion Specifications give OEMs a shared language for assets, jobs, states and KPIs. That language is what enables a mixed fleet to be browsed, subscribed and acted upon in the same way. umati builds on this by curating the Companion Specs for machine tools and organizing conformance testing and plug-and-produce demonstrations, so an integrator isn’t starting from a blank namespace every time a new mill or grinder lands on the floor.

TSN addresses the other half of the problem: making a single converged network carry mixed-criticality traffic without surprises. The pieces most relevant to machine shops are mature enough to buy and deploy in 2025. IEEE 802.1AS-2020 provides sub-microsecond time synchronization across switches and endpoints; 802.1Qbv’s time-aware shaper reserves windows for scheduled traffic; 802.1Qbu/802.3br allow high-priority frames to preempt low-priority ones; 802.1Qci enforces per-stream policing; and 802.1CB adds frame replication and elimination for path redundancy. Together, they turn commodity Ethernet into something schedulable and predictable for motion, triggers and coordinated cells.

The near-term reality in most brownfield plants is a hybrid. OPC UA runs in client/server mode for configuration and on-change subscriptions to MES and SCADA. MQTT remains popular for brokered telemetry to the cloud. TSN is introduced first to support control and motion domains or to harden cell-level determinism, while the rest of the network operates as best-effort VLANs. As engineering teams gain confidence, some are adopting OPC UA PubSub using the UADP binary mapping over Layer 2, making specific telemetry streams deterministic under a TSN schedule without giving up the simplicity of client/server for browsing and security bootstrapping.

Security is finally being treated as integral to connectivity, not an afterthought. Buyers increasingly expect IEC 62443 alignment at both the device (62443‑4‑2) and system (62443‑3‑3) levels, plus evidence of secure development, signed firmware, a software bill of materials and patch cadence. On the protocol side, that means OPC UA Secure Conversation with modern profiles for client/server, TLS 1.3 for brokered flows, certificate management via a Global Discovery Server, and network access controls. On the timing side, authenticated, monitored time with hardware timestamping avoids subtle failures when a grandmaster drifts or drops.

The hard parts are operational, not conceptual. Multi-vendor TSN requires careful feature matching; not every endpoint supports the same subset of Qbv, Qbu, Qci or 802.1AS profiles, and scheduling tools must consider worst-case latency and congestion. Time synchronization needs disciplined clocking—grandmasters with solid holdover, boundary clocks in switches, disciplined endpoints—and practical acceptance criteria such as end-to-end time error under a microsecond where tight coordination is needed. For OPC UA, conformance is not binary; Companion Spec coverage varies by vendor and version, so integrators should ask for NodeSet version IDs and certification reports and test namespaces against their own required data points.

At EMO 2025, visitors can expect to see machine tools that expose OPC UA servers out of the box, umati-labeled demonstrations that show plug-and-produce onboarding into a common dashboard, and TSN-capable switches and network interface cards running bounded-latency traffic alongside best-effort IT flows. Edge gateways that wrap legacy fieldbuses and discrete I/O into OPC UA will also feature prominently, providing a retrofit path for older CNCs without ripping out working assets. The emphasis is shifting from proof-of-concept to scale: fewer marketing slides, more measured latency/jitter data, conformance reports and security design evidence.

Procurement and engineering teams can use three practical filters as they walk the show. First, insist on semantics: ask vendors to demonstrate OPC 40001‑1 and OPC 40501‑1 coverage for the machine’s core states and KPI nodes, and to disclose the exact NodeSet versions implemented. Second, treat time as a resource: for TSN claims, look for hardware support for 802.1AS-2020 and Qbv/Qbu/Qci/CB, scheduling and provisioning via standard models, and measured worst-case latency and jitter under load. Third, verify security posture: device certificates, unique credentials, secure boot and signed updates should be demonstrable; network segmentation and certificate rotation should be part of the integration story, not a future plan.

The direction of travel is clear. Interoperable semantics via OPC UA and umati are becoming procurement requirements, not optional extras. Deterministic transport via TSN is moving from motion islands into mixed-traffic cells. And the connective tissue—time, security, and lifecycle management—is gaining the rigor it always needed. Plants that standardize now will spend less integrating and more producing. EMO 2025 will offer ample evidence that the pieces are ready; the remaining work is disciplined selection and execution.

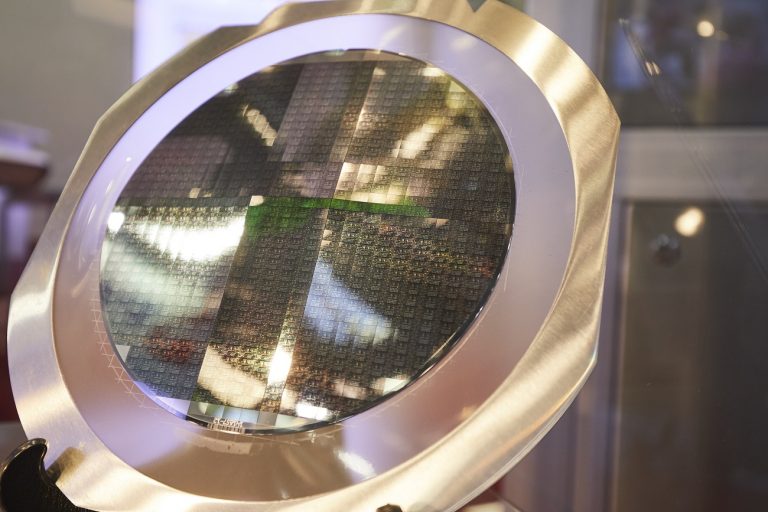

Title photo by ThisIsEngineering

< Back to Automation, AI, Robotics

< Back to Electronics, Components

< Back to Engineering, Industrial…

< Back to IT & Telecommunications

> Here is one of the places where the issuer of a news item is branded.

> Tap buttons or logos to be redirected to the issuers profiles or pages.