At productronica 2025, SCHUNK Electronic Solutions will present its comprehensive portfolio for electronic assembly manufacturing – from proven stand-alone machines to fully integrated inline systems. The focus is on modular, flexible and customised processes that enable highly efficient production. The world’s leading trade fair for electronics development and manufacturing will take place from 18 to 21 November 2025 in Munich.

Electronics are embedded in nearly every modern product – from automotive headlights to electric toothbrushes. Wherever electronic assemblies are produced, SCHUNK Electronic Solutions brings its expertise to the table. Whether for medical technology, aerospace or automotive applications, the company will demonstrate at productronica 2025 how precision, flexibility and cleanliness can be intelligently combined to optimise production efficiency and support long-term growth.

Connected Systems for Modern Electronics Manufacturing

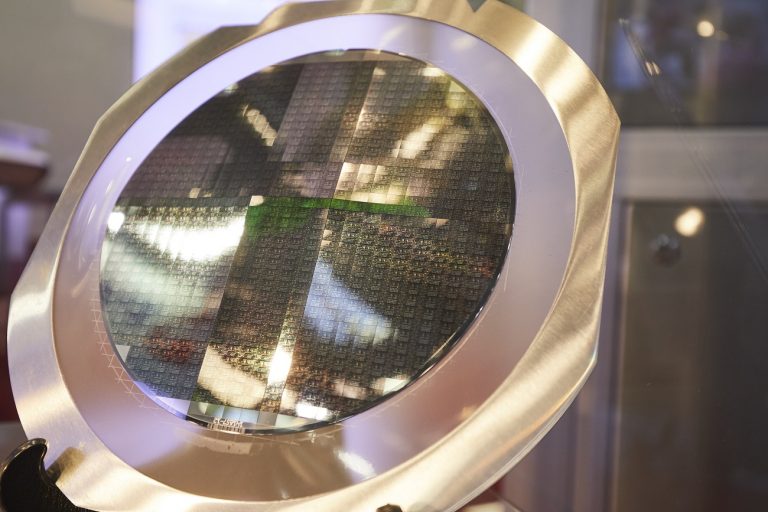

SCHUNK Electronic Solutions stands for high-tech systems in electronics production. The company’s depaneling systems – whether milling, sawing or laser-based – are powerful process modules for separating printed circuit boards and can be flexibly adapted to customer-specific requirements. In addition to depaneling solutions, SCHUNK will showcase end-to-end systems for board handling, including modules for PCB handling and automation of the entire process chain. The dual loader serves as a central interface, enabling integration into overarching automation concepts and allowing manufacturers to meet future requirements with maximum flexibility.

Proven Technology, Maximum Flexibility

The SAR-1300 depaneling system reliably handles a wide variety of PCB layouts by combining milling and sawing technologies. Its patented MAGNOPLATE workpiece carrier system allows quick and flexible changeovers, even with high product variance. Magnetic pins can be positioned in just seconds via simple programming, enabling users to configure their own customised carriers. Another highlight is the Dust-Reduce-Booster, which reduces milling dust by up to 70 percent to ensure clean processes and a healthy production environment. The SAR-1300 also meets rising demands such as unmanned night shifts, increased throughput or long periods of autonomous operation. Equipped with an optional cobot for loading and unloading PCBs, and supported by SCHUNK’s board-handling systems, the SAR-1300 becomes a scalable automation solution.

Precision Depaneling with Laser and Milling Technologies

The SAL-1300 combines laser and milling technology in a single machine – offering new possibilities for applications with the highest quality requirements. The laser separates PCBs without dust and without mechanical stress, making it ideal for delicate components and increasingly miniaturised designs. A wide range of available laser sources ensures the right solution for every material.

Its dual-shuttle system enables parallel or combined laser and milling operations – an ideal setup for sensitive rigid-flex PCBs composed of both rigid and flexible materials.

End-of-Line Complete Solutions from a Single Source

The ILR Performance depaneler is typically integrated inline into a process chain but can also be customised to individual customer workflows – from automated loading to final placement. The trade fair setup, developed in close partnership with automation specialist Omron, demonstrates how the ILR seamlessly completes a process chain and interacts with other systems: an Omron AMR manages loading, while a SCHUNK dual loader transfers the panels. After high-precision depaneling in the ILR, the PCBs pass through a process station that can include testing, cleaning, AOI, dispensing or other required steps.

Subsequently, assemblies are automatically detected, gripped and placed using SCHUNK’s AI-powered 2D Grasping Kit – winner of the HERMES AWARD 2024. The final placement illustrates SCHUNK’s versatility: from palletisers to flat belt conveyors to shuttle-based transfer. The modular design allows expansions even during live operation, ensuring maximum flexibility and future-proofing.

Visit SCHUNK at productronica 2025: Hall A3, Stand 248.

< Back to Electronics, Components

< Back to Engineering, Industrial…

> Here is one of the places where the issuer of a news item is branded.

> Tap buttons or logos to be redirected to the issuers profiles or pages.