In a nutshell:

Silicon carbide (SiC) and gallium nitride (GaN) devices deliver higher efficiency, power density, and regenerative capability in AFEs, spindle/axis inverters, and auxiliary supplies. In machine tools, the result is lower energy per part, less heat, and faster ramp rates.

SiC dominates 1200 V classes (AFE and servo), GaN excels at 400–650 V auxiliary PFC/LLC and high-frequency supplies. A common DC bus enables energy sharing and simple integration of storage/regen.

Success hinges on correct gate drive, layout to control dv/dt/EMI, robust isolation, and reliability validation (power cycling). Supply risk for SiC remains material; second-sourcing is limited.

Machine shops are drilling into energy per part with a rigor once reserved for cycle time. Electricity costs, sustainability goals and grid quality penalties are forcing a rethink of how power is converted, moved and recovered in CNC cells. Silicon carbide (SiC) and gallium nitride (GaN) devices are the enabling components, and in 2025 they’re past the hype curve. At EMO 2025 in Hannover, expect to see front ends that regenerate cleanly to the grid, drives riding common DC buses, and compact auxiliary supplies—all aimed at squeezing losses and heat out of cabinets.

The biggest lever is replacing diode rectifiers and braking resistors with an active front end (AFE) tied to a common DC bus. In a typical 400/480 VAC environment, that bus sits in the 680–760 V range. A SiC-based AFE provides bidirectional power flow, near-unity power factor and compliance with harmonics limits across a wide load range. Efficiency gains of one to two-and-a-half percentage points at rated load are realistic, but the more material benefit is what happens during deceleration and dynamic moves: energy that would have gone to a hot resistor is either shared with other axes on the bus or pushed back to the grid. Depending on duty cycle, the recoverable share of spindle and axis energy during decels can be substantial, and it often shortens payback times to one to three years in multi-shift operations.

On the inverter side, SiC MOSFETs in the 1200 V class are becoming the default for high-performance servo and spindle drives. Lower switching losses let designers run higher carrier frequencies without thermal penalties, improving current ripple and torque smoothness, or keep frequencies the same and reap direct efficiency gains. The trade-off is controlled aggression: SiC’s fast edges raise dv/dt, which raises stress on motor insulation and cables. Long motor leads may require du/dt or sine filters, and older motors can need insulation checks. Gate drivers with high common-mode transient immunity, negative turn-off bias and fast Miller clamps are not luxuries—they are guardrails against false turn-on and destructive events. Thermal design is also a discipline: modern SiC modules and packages can operate to 175–200 °C junction, but mission profiles must keep ΔTj within power-cycling limits to avoid fatigue.

GaN complements rather than replaces SiC in this context. In the 400–650 V range, GaN HEMTs run power-factor correction and LLC stages for auxiliary supplies at hundreds of kilohertz, shrinking magnetics and reducing losses in CNC controllers, HMIs, vision systems and lighting. Their near-zero reverse recovery and low gate charge are strengths, but they demand tight layouts and rigorous EMI control. When cabinet space and thermal budgets are tight, GaN-based SMPS can be an easy win with clear thermal and reliability dividends.

Reliability and standards haven’t gone away just because efficiencies are up. Drives must meet EMC for adjustable-speed systems (EN 61800‑3), functional safety (IEC 61800‑5‑2 for STO, SS1/SS2 and related functions) and electrical safety (IEC 61800‑5‑1). On the component level, expect to see lifetime data tied to temperature and current cycling, HTRB/HTGB stress results and failure analyses that identify bond, die-attach or solder fatigue modes. For grid interaction, AFE behavior under sags, swells and phase imbalance should be characterized; power factor and THD performance should be maintained across loads, not just at nameplate.

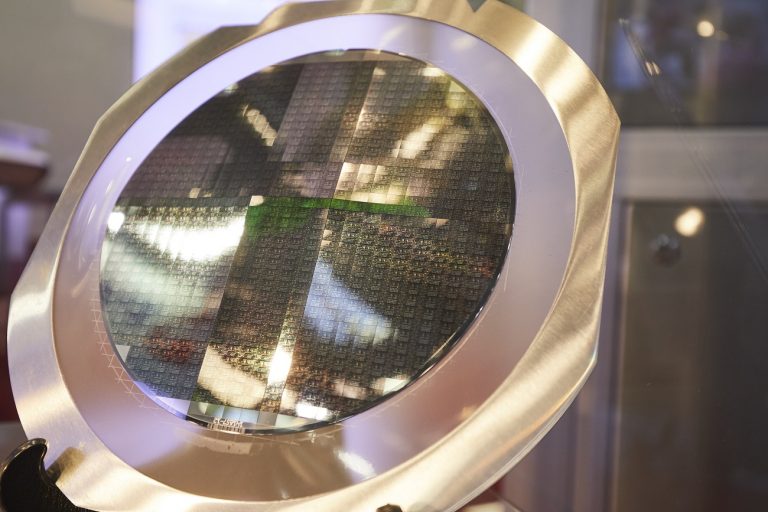

Supply dynamics remain a practical constraint. The industry is expanding 200 mm SiC capacity, and multiple suppliers have announced new fabs and module lines, but tightness persists in some voltage and current classes. Long-term agreements and design flexibility help, but second-sourcing is still limited at the module level. For buyers, that argues for transparent roadmaps, clear lifetime and derating guidance, and thermal stacks that can accommodate alternative modules without full redesign.

What will be visible at EMO 2025 is a shift from isolated “regen options” to system-level energy architectures. Expect AFEs that advertise measured efficiency across the operating envelope, common DC bus cabinets with integrated metering, and dashboards that report kWh per part and regen share. You’ll also see compact, GaN-based auxiliary power supplies that ease cabinet cooling, and more frank conversations about dv/dt, cable filters and motor compatibility. The better booths will have test data rather than slogans: conducted and radiated EMI margins with representative cables, short-circuit response curves for drivers, and power-cycling lifetime plots at realistic ΔTj.

The business case is straightforward. One to two-and-a-half points of conversion efficiency on multi-kilowatt drives, plus regenerative capture, reduces operating costs and heat. Lower heat means fewer nuisance trips and less fan and filter maintenance. Sharing energy on a common DC bus allows smaller AFEs sized to the average rather than the peak. Tie these gains to energy tariffs and uptime metrics and the ROI math closes. The caveats are equally clear: validate motor insulation, specify filters where needed, demand real reliability data, and be honest about supply commitments. In 2025, SiC and GaN are less a bet and more an engineering choice with measurable outcomes.

Title photo by Júlio Riccó

< Back to Electronics, Components

< Back to Engineering, Industrial…

< Back to IT & Telecommunications

> Here is one of the places where the issuer of a news item is branded.

> Tap buttons or logos to be redirected to the issuers profiles or pages.